SMARTFREEZ CRYOPRESERVATION

Freeze smarter. Waste less. Move faster.

Rely on our team of scientists to work alongside you on your cryopreservation challenges.

We deliver customized tech and services for improved performance and accelerated time-to-market of your biologics.

SMARTFREEZ CRYOPRESERVATION

Freeze smarter. Waste less. Move faster.

Rely on our team of scientists to work alongside you on your cryopreservation challenges.

We deliver customized tech and services for improved performance and accelerated time-to-market of your biologics.

Empowering scientists in their cryopreservation challenges!

What do we do?

At Smartfreez, we optimize and develop innovative cryoprocessing systems using advanced computational simulation tools in order to accelerate process development, anticipate scale-up challenges and enable early optimization of large-scale freezing and thawing processes.

Backed by a team of specialized scientists, we go beyond conventional solutions, pushing the boundaries of innovation.

We Reduce Cryopreservation Damage

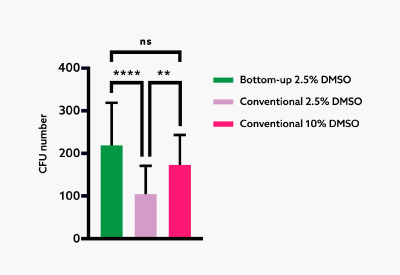

Our systems are designed to minimize cellular stress during cryopreservation by optimizing cooling rates, controlling ice nucleation, and limiting cryoprotectant toxicity.

By reducing mechanical and chemical damage, we improve post-thaw viability and functionality.

80%*

Cell viability (hUCB‐derived MNCs) with 1% DMSO bottom-up freezing

+50%*

Colony-forming with bottom-up freezing method with 2.5% DMSO when compared to conventional radial freezing with 10% DMSO

We Give You the Complete Information with Our Simulators

In-depth data to help you make data-driven decisions with confidence!

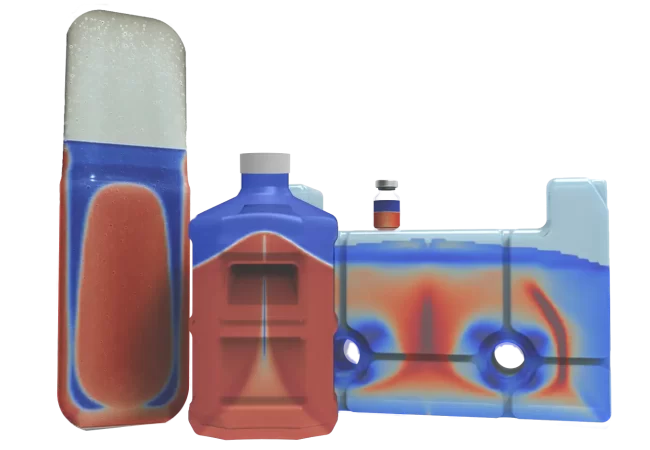

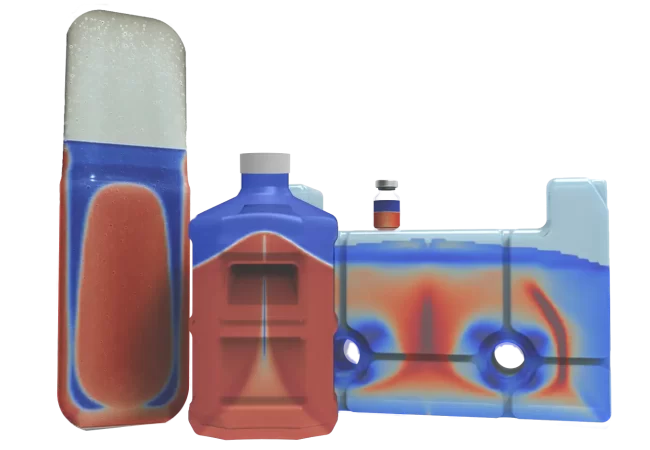

We use advanced computational fluid dynamics (CFD) to give you a clear picture of what happens inside your cryovials, bags, or freeze-thaw systems in real-time conditions.

Our models provide the insight you need to optimize every step of your protocol, letting you troubleshoot before testing, saving time, reducing costs, and improving reproducibility.

We Deliver Scale-Down Accuracy in Freeze-Thaw Cycles

Conventional scale-down methods often rely on small vials inside large chambers.

This method doesn’t reflect the true stresses affecting biologics during freeze-thaw cycles at large scale.

The science that sets us apart:

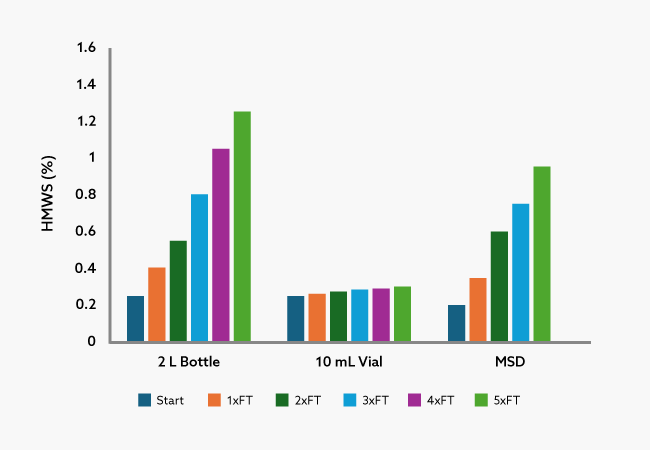

SmartFreez’s Micro Scale-Down technology (MSD), backed by our custom-developed simulation software, is a top-tier solution to accurately mirror proteins’ behaviour in large scale systems. With just 10 mL and using a bench top instrument you’ll be able to replicate a full scale system.

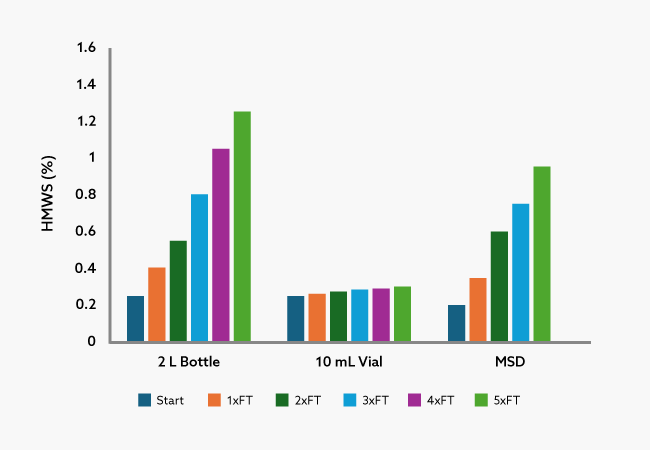

The MSD can generate equivalent aggregation rates that are similar to manufacturing containers undergoing freeze-thaw cycles.

We increase your cell viability with lower cryoprotectant concentrations

Our cryopreservation solutions combine bottom-up directional freezing and controlled ice nucleation. This reduces mechanical stress, leading to higher cell integrity every step of the way.

SmartFreez’s CELL equipment is the best-in-class for controlled rate freezing. It enables cooling rates of up to 5ºC per minute. The freezing method allows lowering cryoprotectant concentrations whilst increasing cell viability and functionality.

We Reduce Cryopreservation Damage

Our systems are designed to reduce freezing-induced mechanical stress through precise control of ice nucleation, uniform ice growth velocity, and custom cooling and thawing rates. They further allow assessment of cryoprotectant performance while supporting concentration reduction to limit toxicity.

By reducing mechanical and chemical damage, we improve post-thaw viability and functionality.

80%*

Cell viability (hUCB‐derived MNCs)

with 1% DMSO bottom-up freezing

+50%*

Colony-forming with bottom-up freezing method with 2.5% DMSO when compared to conventional radial freezing with 10% DMSO

We Give You the Complete Information with Our Simulators

In-depth data to help you make data-driven decisions with confidence!

We use advanced computational fluid dynamics (CFD) to give you a clear picture of what happens inside your cryovials, bags, or freeze-thaw systems in real-time conditions.

Our models provide the insight you need to optimize every step of your protocol, letting you troubleshoot before testing, saving time, reducing costs, and improving reproducibility.

We Deliver Scale-Down Accuracy in Freeze-Thaw Cycles

Conventional scale-down methods often rely on small vials inside large chambers.

This method doesn’t reflect the true stresses affecting biologics during freeze-thaw cycles at large scale.

The science that sets us apart:

SmartFreez’s Micro Scale-Down technology (MSD), backed by our custom-developed simulation software, is a top-tier benchtop instrument to accurately mirror protein’s behaviour in large scale systems. With controlled-rate freezing and thawing in the MSD, using just a 5 mL sample volume, you’ll be able to replicate a full-scale system.

The MSD can generate equivalent aggregation rates that are similar to manufacturing containers undergoing freeze-thaw cycles.

We increase your cell viability and functionality with lower cryoprotectant concentrations

Our cryopreservation solutions combine bottom-up directional freezing and controlled ice nucleation. This reduces mechanical stress, leading to higher cell integrity every step of the way.

SmartFreez’s CELL equipment is the best-in-class for controlled rate freezing. It enables cooling rates of up to 5ºC per minute. The freezing method allows lowering cryoprotectant concentrations whilst increasing cell viability and functionality.

What do we offer?

Innovative cryopreservation systems.

Designed to help you preserve biological samples more efficiently, reducing losses, and achieving more reliable research outcomes.

Are you ready to take cryopreservation to the next level?

Simulation Platform

Accelerate your cryopreservation process through digital insights.

With Smartfreez’s simulation platform you can better understand the freezing process of bags, bottles, and vials. Optimize your cryopreservation methods with efficiency and precision.

Precision Tools

Get precision tools for controlled freezing and stability evaluation.

Our lab instruments help you eliminate supercooling, optimize ice nucleation, and understand how low temperatures impact your formulations.

Accelerate your cryopreservation process through digital insights.

With Smartfreez’s simulation platform you can better understand the freezing process of bags, bottles, and vials. Optimize your cryopreservation methods with efficiency and precision.

Our cryopreservation methodology helps you avoid supercooling, controlled ice nucleation and formation.

Gain early insight into how low temperatures affect your formulations using minimal sample volumes. SmartFreez’s portfolio ranges from lab instruments to large scale manufacturing freezing and thawing systems.

Why Us?

Large Scale Preservation

Preserve sensitive biologic products (protein, cells, gene therapies, blood plasma) at large scales, maintaining their therapeutic benefits upon freezing and thawing.

Optimize Resource Use

Build and validate cryopreservation processes with minimal amounts of product (5 to 100 mL).

Quicker Processes

Accelerate time to market by qualifying cryopreservation processes and methods, with minimal experimental testing.